Copper is a base metal that forms into alloys freely and can easily be combined with a wide range of alloying elements. There are hundreds of copper alloys, each with specific properties that make them suitable for various applications, manufacturing processes, and environments. One of those alloys is 464 Naval Brass.

What Is 464 Naval Brass?

464 Naval Brass is a type of copper-zinc-tin alloy containing around 59% copper, 40% zinc, and 1% tin with a trace amount of lead. The addition of tin provides extra corrosion resistance in seawater and other mildly aggressive environments, and the alloy offers good strength levels combined with excellent hot formability. Because 464 Naval Brass has a maximum lead content of 0.20%, it is considered a lead-free product. The alloy falls into the subfamily of brasses known as alpha-beta or duplex brasses.

Naval Brass is a hard and durable material that provides excellent corrosion resistance, hot workability, and hot forgeability. The alloy receives its name because of its frequent use in marine environments. 464 Naval Brass’s durability and corrosion-resistant qualities make it suitable for both salt and freshwater applications. Alloy 464 is available in sheet, plate, and rod forms in various thicknesses and sizes.

Properties of Naval Brass

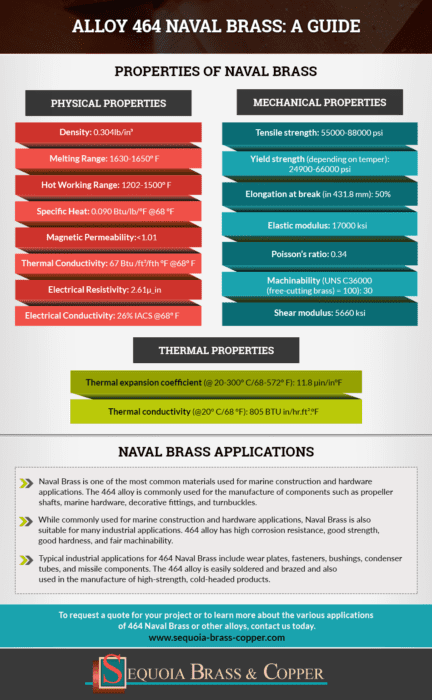

Physical Properties

- Density: 0.304lb/in³

- Melting Range: 1630-1650º F

- Hot Working Range: 1202-1500º F

- Specific Heat: 0.090 Btu/lb/ºF @68 ºF

- Magnetic Permeability:<1.01

- Thermal Conductivity: 67 Btu /ft²/fth ºF @68º F

- Electrical Resistivity: 2.61μ_in

- Electrical Conductivity: 26% IACS @68º F

Mechanical Properties

- Tensile strength: 55000-88000 psi

- Yield strength (depending on temper): 24900-66000 psi

- Elongation at break (in 431.8 mm): 50%

- Elastic modulus: 17000 ksi

- Poisson’s ratio: 0.34

- Machinability (UNS C36000 (free-cutting brass) = 100): 30

- Shear modulus: 5660 ksi

Thermal Properties

- Thermal expansion coefficient (@ 20-300° C/68-572° F): 11.8 μin/in°F

- Thermal conductivity (@20° C/68 °F): 805 BTU in/hr.ft².°F

Naval Brass Applications

Naval Brass is one of the most common materials used for marine construction and hardware applications. The 464 alloy is commonly used for the manufacture of components such as propeller shafts, marine hardware, decorative fittings, and turnbuckles.

While commonly used for marine construction and hardware applications, Naval Brass is also suitable for many industrial applications. 464 alloy has high corrosion resistance, good strength, good hardness, and fair machinability.

Typical industrial applications for 464 Naval Brass include wear plates, fasteners, bushings, condenser tubes, and missile components. The 464 alloy is easily soldered and brazed and also used in the manufacture of high-strength, cold-headed products.

Choosing Sequoia Brass & Copper for Naval Brass

464 Naval Brass is a copper-zinc-tin alloy commonly used throughout the marine industry. The material is exceptionally resistant to corrosion, making it ideal for both fresh and saltwater applications. In addition to its durability and ability to withstand seawater and other mildly aggressive environments, 464 alloy is known for its hardness and is suitable for a variety of industrial applications. Naval Brass is an outstanding alloy used for hot forming and hot forging applications and also has fair machinability.

When choosing a distributor, it is essential to select an established supplier with a reputation for quality. Sequoia Brass & Copper Inc. is an industry-leading supplier of non-ferrous metals in plate, bar, and sheet forms. We offer a broad mix of products and services, featuring unsurpassed quality, including 464 Naval Brass, and have been serving the metal fabrication industries throughout North America since 1983.

Our highly qualified team is dedicated to outstanding customer service and committed to providing our customers with the highest quality materials available. To request a quote for your project or to learn more about the various applications of 464 Naval Brass or other alloys, contact us today.