Electrolytic tough pitch (ETP) copper is the most common type of copper available. It is highly conductive, which makes it an ideal material for carrying electric current in a broad spectrum of applications. ETP copper, or C11000 copper, is considered commercially pure and has a minimum purity of 99.90% copper.

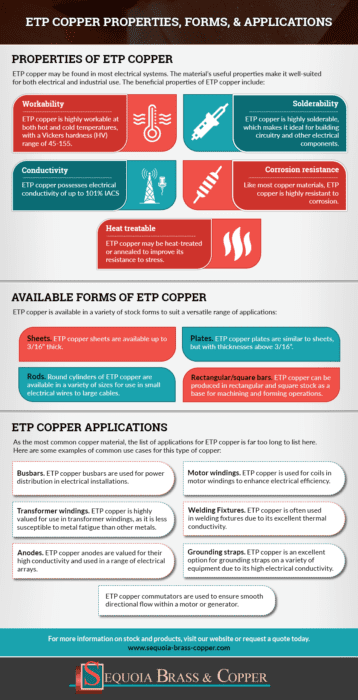

Properties of ETP Copper

ETP copper may be found in most electrical systems. The material’s useful properties make it well-suited for both electrical and industrial use. The beneficial properties of ETP copper include:

- Workability. ETP copper is highly workable at both hot and cold temperatures, with a Vickers hardness (HV) range of 45-155.

- Solderability. ETP copper is highly solderable, which makes it ideal for building circuitry and other electrical components.

- Conductivity. ETP copper possesses electrical conductivity of up to 101% IACS

- Corrosion resistance. Like most copper materials, ETP copper is highly resistant to corrosion.

- Heat treatable. ETP copper may be heat-treated or annealed to improve its resistance to stress.

Available Forms of ETP Copper

ETP copper is available in a variety of stock forms to suit a versatile range of applications:

- Sheets. ETP copper sheets are available up to 3/16” thick.

- Plates. ETP copper plates are similar to sheets, but with thicknesses above 3/16”.

- Rods. Round cylinders of ETP copper are available in a variety of sizes for use in small electrical wires to large cables.

- Rectangular/square bars. ETP copper can be produced in rectangular and square stock as a base for machining and forming operations.

ETP Copper Applications

As the most common copper material, the list of applications for ETP copper is far too long to list here. Here are some examples of common use cases for this type of copper:

- Busbars. ETP copper busbars are used for power distribution in electrical installations.

- Motor windings. ETP copper is used for coils in motor windings to enhance electrical efficiency.

- Transformer windings. ETP copper is highly valued for use in transformer windings, as it is less susceptible to metal fatigue than other metals.

- Welding Fixtures. ETP copper is often used in welding fixtures due to its excellent thermal conductivity.

- Anodes. ETP copper anodes are valued for their high conductivity and used in a range of electrical arrays.

- Grounding straps. ETP copper is an excellent option for grounding straps on a variety of equipment due to its high electrical conductivity.

- ETP copper commutators are used to ensure smooth directional flow within a motor or generator.

C11000 Copper From Sequoia Brass & Copper

At Sequoia Brass & Copper, we guarantee the highest quality C11000 copper on the market. We are pleased to provide only the purest metal sheets, plates, and bars for use by myriad industries. Our extensive selection of materials also includes an expansive list of copper, brass, and bronze, with numerous alloys, shapes, and sizes to meet the needs of every application.

Since 1983, Sequoia Brass & Copper has been a preferred industry provider of superior metal products. All of our materials are cut and shaped on demand in our ISO 9001:2015-certified facility in Hayward, California. Our extensive quality assurance procedures ensure that all of our products are cut to exceptionally tight tolerances. Our convenient location and sizable warehouse allow us to provide competitive pricing and shipping rates for all of our products.

For more information on stock and products, visit our website or request a quote today.