Due to gradual oxidation, copper naturally weathers and corrodes over time. However, it’s possible to protect copper materials from this weathering with the right measures.

Sequoia Brass & Copper is a trusted domestic supplier of copper and other products for customers in the metal fabrication industries, working to earn our customers’ confidence and loyalty. Our team seeks to provide the best solutions for our customers, with a service-oriented business history going back to 1983.

What Is Copper Weathering?

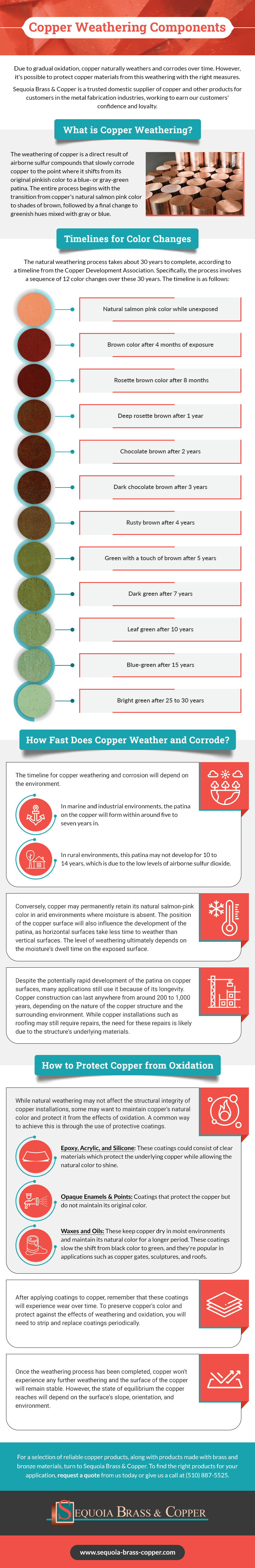

The weathering of copper is a direct result of airborne sulfur compounds that slowly corrode copper to the point where it shifts from its original pinkish color to a blue- or gray-green patina. The entire process begins with the transition from copper’s natural salmon pink color to shades of brown, followed by a final change to greenish hues mixed with gray or blue.

Timelines for Color Changes

The natural weathering process takes about 30 years to complete, according to a timeline from the Copper Development Association. Specifically, the process involves a sequence of 12 color changes over these 30 years. The timeline is as follows:

- Natural salmon pink color while unexposed

- Brown color after 4 months of exposure

- Rosette brown color after 8 months

- Deep rosette brown after 1 year

- Chocolate brown after 2 years

- Dark chocolate brown after 3 years

- Rusty brown after 4 years

- Green with a touch of brown after 5 years

- Dark green after 7 years

- Leaf green after 10 years

- Blue-green after 15 years

- Bright green after 25 to 30 years

How Fast Does Copper Weather and Corrode?

The timeline for copper weathering and corrosion will depend on the environment. For example, the patina on the copper will form within around five to seven years in marine and industrial environments. Meanwhile, this patina may not develop for 10 to 14 years in rural environments, which is due to the low levels of airborne sulfur dioxide. Conversely, copper may permanently retain its natural salmon-pink color in arid environments where moisture is absent. The position of the copper surface will also influence the development of the patina, as horizontal surfaces take less time to weather than vertical surfaces. The level of weathering ultimately depends on the moisture’s dwell time on the exposed surface.

Despite the potentially rapid development of the patina on copper surfaces, many applications still use it because of its longevity. Copper construction can last anywhere from around 200 to 1,000 years, depending on the nature of the copper structure and the surrounding environment. While copper installations such as roofing may still require repairs, the need for these repairs is likely due to the structure’s underlying materials.

How to Protect Copper from Oxidation

While natural weathering may not affect the structural integrity of copper installations, some may want to maintain copper’s natural color and protect it from the effects of oxidation. A common way to achieve this is through the use of protective coatings. These coatings could consist of clear materials like epoxy, acrylic, and silicone, which protect the underlying copper while allowing the natural color to shine. If the original copper color is not desired, you may opt for opaque enamels, paints, or other coatings.

In addition, you can use waxes and oils to keep copper dry in moist environments and maintain its natural color for a longer period. These coatings slow the shift from black color to green, and they’re popular in applications such as copper gates, sculptures, and roofs.

However, after applying coatings to copper, remember that these coatings will experience wear over time, leaving copper exposed to moisture and other elements. To preserve copper’s color and protect against the effects of weathering and oxidation, you will need to strip and replace coatings periodically.

High-Quality Copper Products from Sequoia Brass & Copper

Once the weathering process has been completed, copper won’t experience any further weathering and the surface of the copper will remain stable. However, the state of equilibrium the copper reaches will depend on the surface’s slope, orientation, and environment.

For a selection of reliable copper products, along with products made with brass and bronze materials, turn to Sequoia Brass & Copper. To find the right products for your application, request a quote from us today or give us a call at (510) 887-5525.