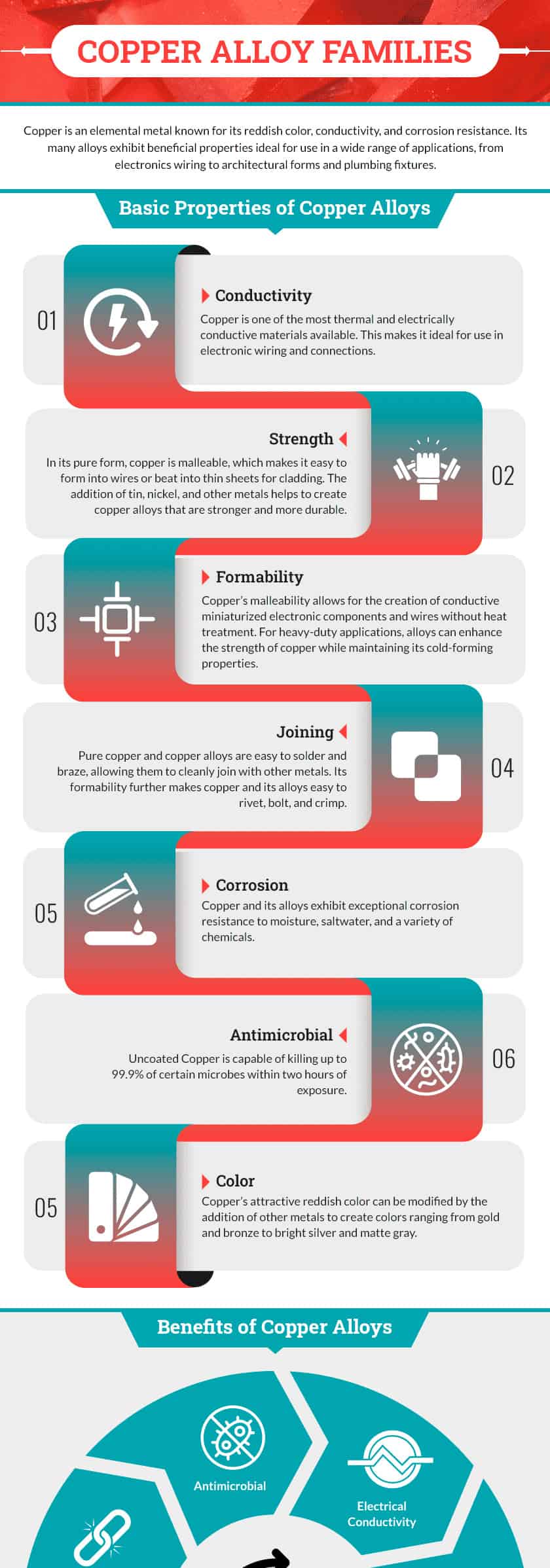

Copper is an elemental metal known for its reddish color, conductivity, and corrosion resistance. Its many alloys exhibit beneficial properties ideal for use in a wide range of applications, from electronics wiring to architectural forms and plumbing fixtures. At Sequoia Brass & Copper, we offer superior quality copper alloys for virtually any application. Here, we offer an overview of our copper alloys as well as their characteristics, benefits, and uses.

What Are Copper Alloys?

Copper is a naturally occurring elemental metal. While pure copper is often used in manufacturing, the element also combines easily with a number of metals to form alloys that enhance thermal and electrical conductivity, strength, corrosion resistance, and antimicrobial properties. Copper’s basic properties include:

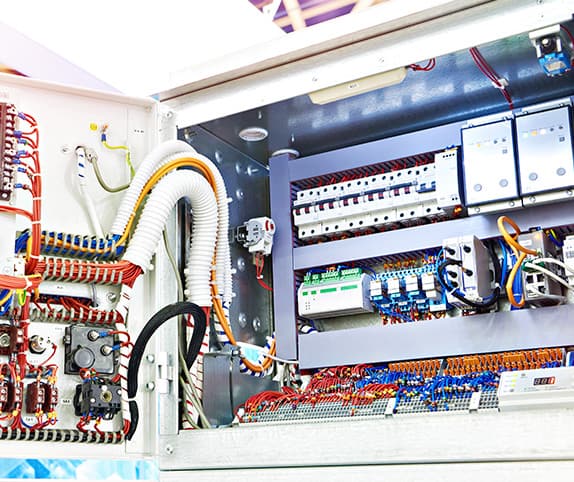

- Conductivity. Copper is one of the most thermal and electrically conductive materials available. This makes it ideal for use in electronic wiring and connections.

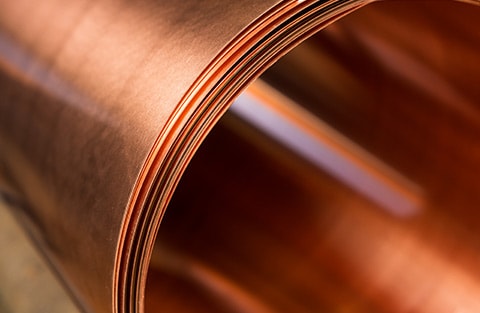

- Strength. In its pure form, copper is malleable, which makes it easy to form into wires or beat into thin sheets for cladding. The addition of tin, nickel, and other metals helps to create copper alloys that are stronger and more durable.

- Formability. Copper’s malleability allows for the creation of conductive miniaturized electronic components and wires without heat treatment. For heavy-duty applications, alloys can enhance the strength of copper while maintaining its cold forming properties.

- Joining. Pure copper and copper alloys are easy to solder and braze, allowing them to cleanly join with other metals. Its formability further makes copper and its alloys easy to rivet, bolt, and crimp.

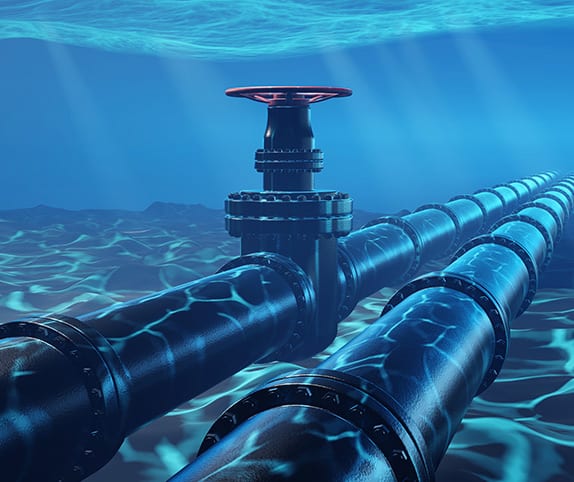

- Corrosion. Copper and its alloys exhibit exceptional corrosion resistance to moisture, saltwater, and a variety of chemicals.

- Antimicrobial. Uncoated Copper is capable of killing up to 99.9% of certain microbes within two hours of exposure.

- Color. Copper’s attractive reddish color can be modified by the addition of other metals to create colors ranging from gold and bronze to bright silver and matte gray.

Copper Alloy Applications

When combined with other metals, copper produces a highly versatile range of alloys that can be used in many industries and applications, including:

Benefits of Copper Alloys

Copper and copper alloys offer a wide range of benefits, including:

Electrical Conductivity

As previously mentioned, copper offers good electrical conductivity. While some copper alloys are more conductive than others, all copper alloys are electrically conductive to some degree.

High Thermal Conductivity

Copper is an excellent conductor of heat, making it suitable for applications requiring rapid heat transfer.

Non-Magnetic.

Copper is non-sparking and non-magnetic, making it an ideal choice for special tools and military applications.

Recyclable

Copper can be recycled an infinite amount of times without losing any of its properties.

Corrosion Resistance

Copper has low reactivity, meaning it doesn’t tend to corrode when exposed to different elements such as moisture, certain chemicals, etc.

Durability

Copper and copper alloys are very strong and durable, allowing for long-lasting products and equipment.

Antimicrobial Properties

The EPA has registered copper as antimicrobial, and it is effective against MRSA, E. Coli, and other bacteria. Copper alloys have specifically been shown to reduce microbial contamination, making them an excellent supplement to existing infection control practices.

Copper Alloy Families

With over 400 variations on the market, copper alloys are engineered with specific properties tailored to meet the needs of a wide range of products and applications. Below is a list of the most popular copper alloys and their features:

- Copper. In its purest form, copper exhibits thermal and electrical conductivity unmatched by any other metal on the market. It readily bonds with a wide variety of metals to produce numerous useful alloys.

- Brass. The brass family of copper alloys incorporates zinc and other metals in different ratios to enhance strength, ductility, conductivity, corrosion resistance, and machinability.

- Tin Brass. Tin brass is a member of the brass alloy family that includes copper, up to 40% zinc, and up to 3% tin. This high-strength, exceptionally corrosion-resistant brass is ideal for use in naval and marine applications.

- Silicon Red Brass. Silicone red brass is a type of brass with less than 20% zinc and up to 6% silicon. An exceptionally strong alloy, silicon red brass is used for fail-safe valve components, gears, and bearings that require high corrosion resistance.

- Bronze. The bronze family of copper is composed of copper alloys blended with tin. Its strength, corrosion resistance, and attractive finish make it popular for marine, engineering, and architectural applications.

- Phosphor Bronze. Small amounts of phosphorus enhance bronze’s fatigue and wear resistance, for a harder alloy ideal for high-pressure, high-tension applications such as springs, gears, bearings, shafts, and fasteners.

- Aluminum Bronze. Aluminum bronze includes between 5% and 12% aluminum, along with various combinations of other metals. This produces alloys with superior strength, corrosion resistance, toughness, and wear resistance.

- Silicon Bronze. Silicon bronze alloys incorporate 3% silicon and 1% manganese to enhance ductility, strength, and weldability. They are perfect for architectural applications that require both beauty and functionality.

- Copper Nickel. Copper nickel alloys are a family of copper alloys engineered for optimal resistance to corrosion from seawater in marine environments.

- Nickel Silver. Nickel silver is named for its pleasing silver color. It is made up of copper, zinc, and between 10% and 20% nickel, and it offers the same level of corrosion resistance and strength as other brasses.

Copper Alloys from Sequoia Brass & Copper

At Sequoia Brass and Copper, we are pleased to offer a wide range of copper alloys, including:

Alloy 101: Oxygen-Free Electronic (OFE)

Also known as Oxygen-Free High Thermal Conductivity (OFHC) Copper, OFE copper is engineered in a specialized oxygen-free environment to create an alloy with 99.99% copper. The highly purified copper provides exceptional electrical and thermal conductivity.

Alloy 110: Electrolytic (ETP) Copper

ETP copper is manufactured for 99.9% purity, and it is the most popular copper alloy for electrical and thermal applications due to its exceptional conductivity and high ductility.

Alloy 122: Deoxidized High Phosphorus (DHP) Copper

DHP copper exhibits the same electrical and thermal capabilities as 110, but is easier to form, braze and solder.

Alloy 145: Tellurium Copper

Composed of copper and 0.4–0.7% tellurium, this alloy is valued for its exceptional machinability and electrical conductivity.

Contact Sequoia Brass & Copper Today!

Since 1983, Sequoia Brass & Copper has been manufacturing quality nonferrous metal plates, sheets, and bars to meet the needs of virtually any application. Contact us today to learn more about our selection of copper and copper alloy products.