At Sequoia Brass & Copper, we’ve supplied brass, bronze, copper, and other non-ferrous metal alloys to metal fabrication customers across North America for over 30 years. Our materials are available in bar, plate, sheet, and other forms. One of our core brass offerings is 353 brass.

353 Brass—also referred to as engraver’s brass—is a copper-zinc alloy recognized for its unique combination of strength, wear resistance, and machinability. Below, we provide an overview of the key properties and typical applications of this material.

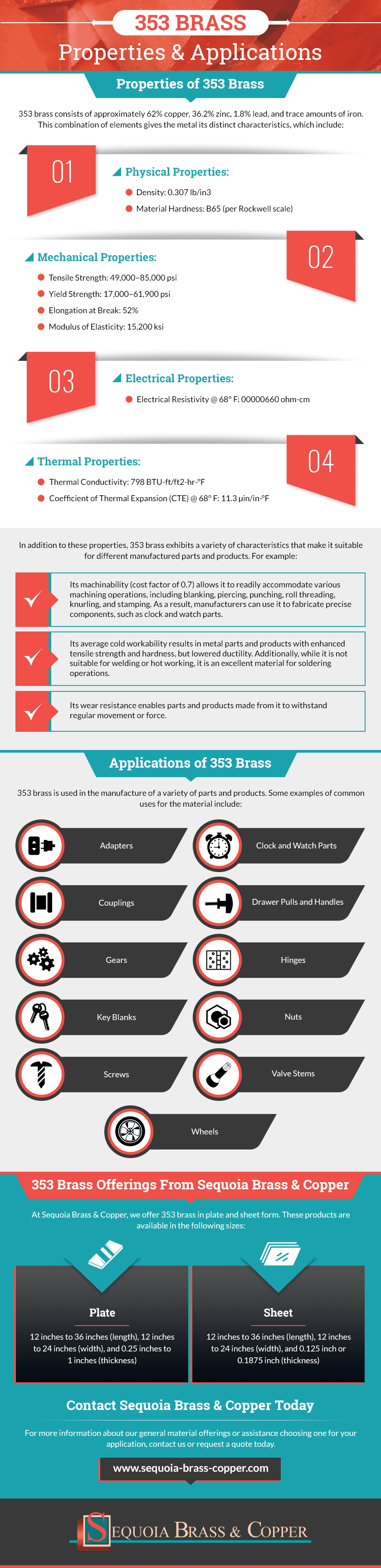

Properties of 353 Brass

353 brass consists of approximately 62% copper, 36.2% zinc, 1.8% lead, and trace amounts of iron. This combination of elements gives the metal its distinct characteristics, which include:

Physical Properties:

- Density: 0.307 lb/in3

- Material Hardness: B65 (per Rockwell scale)

Mechanical Properties:

- Tensile Strength: 49,000–85,000 psi

- Yield Strength: 17,000–61,900 psi

- Elongation at Break: 52%

- Modulus of Elasticity: 15,200 ksi

Electrical Properties:

- Electrical Resistivity @ 68° F: 00000660 ohm-cm

Thermal Properties:

- Thermal Conductivity: 798 BTU-ft/ft2-hr-°F

- Coefficient of Thermal Expansion (CTE) @ 68° F: 11.3 µin/in-°F

In addition to these properties, 353 brass exhibits a variety of characteristics that make it suitable for different manufactured parts and products. For example:

- Its machinability (cost factor of 0.7) allows it to readily accommodate various machining operations, including blanking, piercing, punching, roll threading, knurling, and stamping. As a result, manufacturers can use it to fabricate precise components, such as clock and watch parts.

- Its average cold workability results in metal parts and products with enhanced tensile strength and hardness, but lowered ductility. Additionally, while it is not suitable for welding or hot working, it is an excellent material for soldering operations.

- Its wear resistance enables parts and products made from it to withstand regular movement or force.

Applications of 353 Brass

353 brass is used in the manufacture of a variety of parts and products. Some examples of common uses for the material include:

- Adapters

- Clock and watch parts

- Couplings

- Drawer pulls and handles

- Gears

- Hinges

- Key blanks

- Nuts

- Screws

- Valve stems

- Wheels

353 Brass Offerings From Sequoia Brass & Copper

At Sequoia Brass & Copper, we offer 353 brass in plate and sheet form. These products are available in the following sizes:

Plate: 12 inches to 36 inches (length), 12 inches to 24 inches (width), and 0.25 inches to 1 inches (thickness)

Sheet: 12 inches to 36 inches (length), 12 inches to 24 inches (width), and 0.125 inch or 0.1875 inch (thickness)

Contact Sequoia Brass & Copper Today

At Sequoia Brass & Copper, we are an experienced and knowledgeable supplier of non-ferrous metal alloy materials. If you need 353 brass or another brass, bronze, or copper alloy, we’ve got you covered. To learn more about our 353 brass offerings, visit our 353 brass catalog page or submit a request for information. For more information about our general material offerings or assistance choosing one for your application, contact us or request a quote today. Our team is always ready and willing to answer and address any questions or concerns.