Tellurium copper—also referred to as Alloy 145, Alloy C14500, 145 half-hard tellurium, and TeCu—is a copper-based alloy that contains varying amounts of tellurium and phosphorus. The tellurium content typically ranges between 0.4–0.7%, while the phosphorus content ranges between 0.004–0.12%.

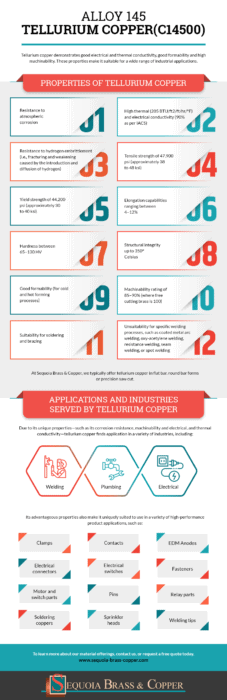

Tellurium copper demonstrates good electrical and thermal conductivity, good formability and high machinability. These properties make it suitable for a wide range of industrial applications.

Properties of Tellurium Copper

Some of the mechanical, chemical, electrical, and manufacturing properties characteristic of tellurium copper include:

- Resistance to atmospheric corrosion

- High thermal (205 BTU/ft2/ft/hr/°F) and electrical conductivity (90% as per IACS)

- Resistance to hydrogen embrittlement (i.e., fracturing and weakening caused by the introduction and diffusion of hydrogen)

- Tensile strength of 47,900 psi (approximately 38 to 48 ksi)

- Yield strength of 44,200 psi (approximately 30 to 40 ksi)

- Elongation capabilities ranging between 4–12%

- Hardness between 65–130 HV

- Structural integrity up to 350° Celsius

- Good formability (for cold and hot forming processes)

- Machinability rating of 85–90% (where free cutting brass is 100)

- Suitability for soldering and brazing

- Unsuitability for specific welding processes, such as coated metal arc welding, oxy-acetylene welding, resistance welding, seam welding, or spot welding

At Sequoia Brass & Copper, we typically offer tellurium copper in flat bar, round bar forms or precision saw cut. However, the raw material is also available in hollow rod, hexagonal rod, tube, and wire forms.

Applications and Industries Served by Tellurium Copper

Due to its unique properties—such as its corrosion resistance, machinability and electrical, and thermal conductivity—tellurium copper finds application in a variety of industries, including:

- Welding

- Plumbing

- Electrical

Its advantageous properties also make it uniquely suited to use in a variety of high-performance product applications, such as:

- Clamps

- Contacts

- EDM Anodes

- Electrical connectors

- Electrical switches

- Fasteners

- Motor and switch parts

- Pins

- Relay parts

- Soldering coppers

- Sprinkler heads

- Welding tips

Sequoia Brass & Copper’s Tellurium Copper Offerings

Tellurium copper’s unique properties make it an excellent source material for many industrial applications, including the welding, plumbing, and electrical industries.

At Sequoia Brass & Copper, we are an industry-leading supplier of high-quality non-ferrous metals. We offer an extensive selection of copper materials—including tellurium copper bars and rods—to our customers. Our Alloy 145 (C14500) rectangular tellurium copper bars are available in standard 6-inch widths with thickness ranging from 0.25 to 1.25 inches and lengths ranging between 12 to 72 inches, while our Alloy 145 (C14500) tellurium copper rods are available with outer diameters ranging from .25 to 3 inches and lengths ranging between 6 to 72 inches. Sequoia Brass & Copper offers precision saw-cutting for Tellurium Copper to meet your application needs.

If you’d like to learn more about our material offerings, contact us, or request a free quote today.