260 brass—also referred to as cartridge brass, yellow brass, and 70/30 brass—is a copper-zinc alloy with a distinct shiny, yellow appearance. Its functional and aesthetic qualities—such as its bending, corrosion resistance, and tonal quality—make it well-suited for use in parts and products ranging from home furnishings to artwork to musical instruments.

Properties of 260 Brass

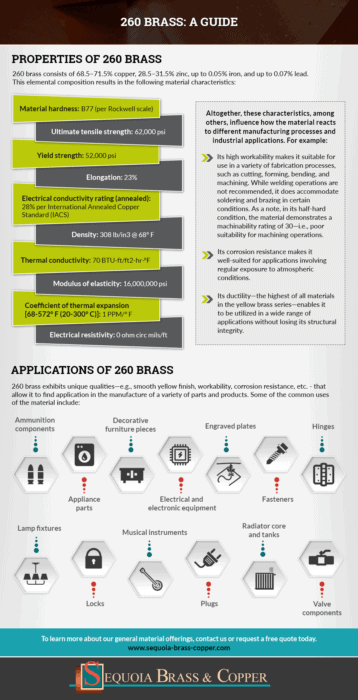

260 brass consists of 68.5–71.5% copper, 28.5–31.5% zinc, up to 0.05% iron, and up to 0.07% lead. This elemental composition results in the following material characteristics:

- Material hardness: B77 (per Rockwell scale)

- Ultimate tensile strength: 62,000 psi

- Yield strength: 52,000 psi

- Elongation: 23%

- Electrical conductivity rating (annealed): 28% per International Annealed Copper Standard (IACS)

- Density: 308 lb/in3 @ 68° F

- Thermal conductivity: 70 BTU-ft/ft2-hr-°F

- Modulus of elasticity: 16,000,000 psi

- Coefficient of thermal expansion [68-572° F (20-300° C)]: 1 PPM/° F

- Electrical resistivity: 0 ohm circ mils/ft

Altogether, these characteristics, among others, influence how the material reacts to different manufacturing processes and industrial applications. For example:

- Its high workability makes it suitable for use in a variety of fabrication processes, such as cutting, forming, bending, and machining. While welding operations are not recommended, it does accommodate soldering and brazing in certain conditions. As a note, in its half-hard condition, the material demonstrates a machinability rating of 30—i.e., poor suitability for machining operations.

- Its corrosion resistance makes it well-suited for applications involving regular exposure to atmospheric conditions.

- Its ductility—the highest of all materials in the yellow brass series—enables it to be utilized in a wide range of applications without losing its structural integrity.

Applications of 260 Brass

260 brass exhibits unique qualities—e.g., smooth yellow finish, workability, corrosion resistance, etc.—that allow it to find application in the manufacture of a variety of parts and products. Some of the common uses of the material include:

- Ammunition components

- Appliance parts

- Decorative furniture pieces

- Electrical and electronic equipment

- Engraved plates

- Fasteners

- Hinges

- Lamp fixtures

- Locks

- Musical instruments

- Plugs

- Radiator core and tanks

- Valve components

260 Brass Offerings From Sequoia Brass & Copper

At Sequoia Brass & Copper, we offer 260 brass in plate and sheet form. These products are available in the following sizes:

- Plate: 36” wide x 96” long from 1/4” to 1/2” thick

- Sheet: 36” wide x 96” long from .020” to 3/16” thick

Contact Sequoia Brass & Copper Today

For over three decades, Sequoia Brass & Copper has supplied high-quality nonferrous metals, such as 260 brass. By maintaining high quality standards for all of our materials, we ensure that we meet and exceed the expectations of our customers. If you need brass, bronze, or copper for your next project, we can deliver.

For more information on our 260 brass offerings, visit our bronze 260 page or submit a request for information. To learn more about our general material offerings, contact us or request a free quote today. Our team is always ready and willing to answer and address any questions or concerns.