For almost 40 years, Sequoia Brass & Copper has been a leading domestic supplier of top-notch copper and brass alloys, serving the metal fabrication industry across North America with an unwavering commitment to quality and excellence. Our philosophy is based on earning the trust and confidence of our customers by maintaining high expectations for ourselves and our employees.

The Sequoia team is dedicated to serving and finding ways to satisfy the needs of the metal-using public. With a focus on customer satisfaction, we are a service-oriented company that is committed to providing the highest quality in both materials and customer response. Our aim is to demonstrate that our service shines and we believe that the key to achieving this is by putting our customers first. With a strong emphasis on building and maintaining relationships with our customers, Sequoia Brass & Copper strives to provide exceptional customer service and top-quality brass alloys that meet the unique needs of each client.

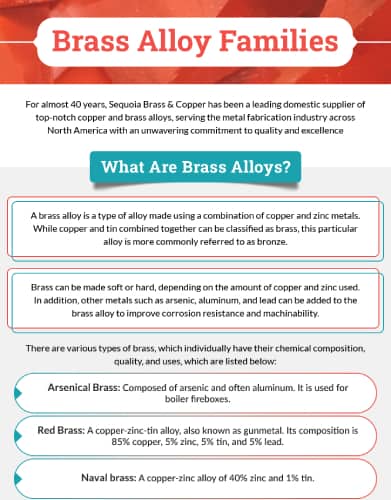

What Are Brass Alloys?

A brass alloy is a type of alloy made using a combination of copper and zinc metals. While copper and tin combined together can be classified as brass, this particular alloy is more commonly referred to as bronze. There are various types of brass, which individually have their chemical composition, quality, and uses, which are listed below:

- Arsenical brass: Composed of arsenic and often aluminum. It is used for boiler fireboxes.

- Red brass: A copper-zinc-tin alloy, also known as gunmetal. Its composition is 85% copper, 5% zinc, 5% tin, and 5% lead.

- Naval brass: A copper-zinc alloy of 40% zinc and 1% tin.

- Cartridge brass: A popular type of brass alloy, consisting of 30% zinc brass, is ideal for ammunition cases due to its excellent cold-working properties.

- Leaded brass: Leaded brass is an alpha-beta brass with additional lead content that is easily machined.

- Manganese brass: Made of 70% copper, 29% zinc, and 1.3% manganese, and is used to make golden dollar coins in the United States.

- Lead-free brass: Lead-free brass alloys consist of less than 0.25% lead material.

- Yellow brass: Contains 33% zinc.

Brass can be made soft or hard, depending on the amount of copper and zinc used. In addition, other metals such as arsenic, aluminum, and lead can be added to the brass alloy to improve corrosion resistance and machinability.

Brass Alloys Applications

Brass has many applications in both the manufacturing and decorative sectors. Since it resembles gold, it is frequently used in the creation of decorative components and architecture. Furthermore, its corrosion-resistant properties make it ideal for applications requiring low friction.

Below are examples of brass applications in various sectors:

Properties of Brass Alloys

Because brass is composed of different combinations of copper and zinc, its properties may vary depending on the proportions of the two metals. Here is a list of properties of brass alloys:

High melting point

Brass has a high melting point of about 900°C (1652°F). However, the melting point varies depending on the composition of metals in the alloy.

Stress-cracking potential

The enhanced strength and stiffness of brass in comparison to pure copper make it more vulnerable to stress-cracking.

Non-ferromagnetic

Its non-ferromagnetic properties make it easy to recycle the alloy.

Malleability and formality

Brass can be formed into any shape required for a product. Furthermore, it is easy to work or cast, whether hot or cold.

Antibacterial

Brass is a poor breeding ground for bacteria, making it ideal for bathroom fixtures, doorknobs, and medical equipment.

Brass Alloy Families

The chemical composition of brass alloys categorizes them into various families of grades. Below are the family types of brass alloys:

Alloy 260

Alloy 260 is also known as cartridge brass and has good cold working properties. Its applications include manufacturing ammunition, automobiles, hardware, and fasteners.

Alloy 272

Also known as yellow brass, this alloy is mostly used in industrial and architectural applications.

Alloy 330

iA type of brass alloy mostly used when high machinability is crucial. With its low lead composition, it is often used to produce pipes.

Alloy 353

A popular choice for producing intricate, precision components like clock and watch parts due to its exceptional machinability and accuracy.

Alloy 360

Free-cutting brass, the most prevalent type of brass, is widely used in the production of hardware components, fittings, valves, and fasteners due to its exceptional machinability, formability, and compatibility with soldering and brazing operations.

Alloy 385

It is also known as architectural bronze and is mostly used for architectural and construction purposes.

Alloy 464

Also known as naval brass, this alloy is known to have high corrosion resistance. Alloy 464 is also malleable and welded, bent, drawn, or soldered to any shape.

Alloy C48200 – C48500

A type of brass alloy used for machining and is available in rounds.

Find the Best Brass to Meet Your Metal Needs

Brass is a fascinating metal alloy with numerous properties that make it a valuable material in a wide range of applications, from decorative to mechanical and even musical. At Sequoia Brass and Copper, we understand the importance of finding the right brass alloy to meet your specific industrial needs. Whether you’re searching for a particular finish or require a certain level of durability, our knowledgeable consultants are ready to help you identify the perfect brass solution. Contact us today to request a quote, and don’t hesitate to reach out to us at (510) 887-5525 to gain a deeper understanding of the metal supplies we offer.