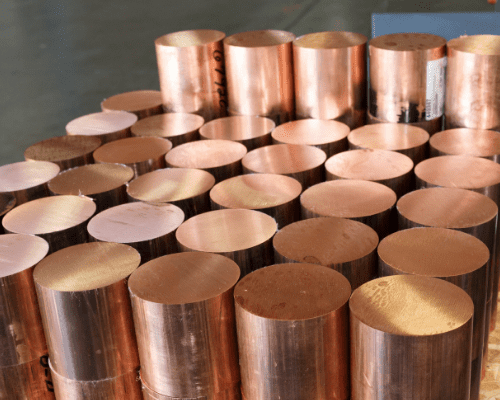

Sequoia Brass & Copper is a leading distributor of copper metals.

Copper is highly ductile and can be easily worked into wire, sheet, plate, bar, rod, tube, and pipe. The copper metal is highly conductive of electricity and heat, as well as relatively corrosion resistant. We specialize in Oxygen-Free copper and carry a substantial inventory of all copper products at our Hayward, California warehouse. All of our copper metal stock sizes are listed on their designated product page and can be ordered online or by submitting the request a quote form. All copper metals can be slit or cut to order to your specifications. With our competitive pricing and shipping rates, there is no need to look anywhere else to find high quality copper metals.