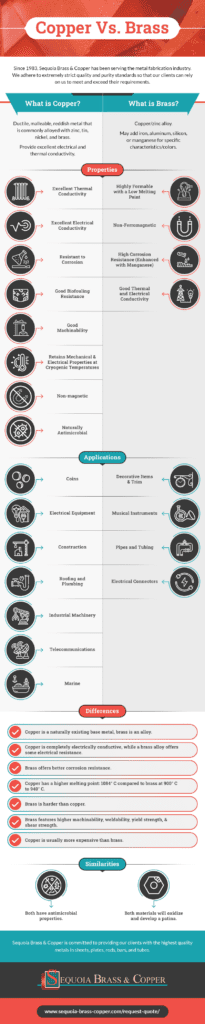

When choosing a material for your project, it’s important to select one with the appropriate qualities to best support your application. Understanding the difference between brass and copper is essential when making these decisions. At Sequoia Brass & Copper, we specialize in providing high-quality materials, including oxygen-free copper, brass, and bronze, for metal fabricators. If you’re considering brass vs. copper, we can help you determine which one is right for you.

What Is Copper?

Copper is a naturally occurring metal that’s highly malleable, though it’s not very hard nor strong. It’s non-magnetic and resists corrosion, with good thermal, conductivity, excellent electrical conductivity and low chemical reactivity. Because it retains its electrical and mechanical properties even at cryogenic temperatures, copper finds a number of uses across industries:

- Coins

- Electrical equipment

- Construction and roofing

- Automotive

- Pipes and plumbing

- Industrial machinery

- Telecommunications

- Marine applications

What Is Brass?

Brass is a copper/zinc alloy, though other metals (like iron, aluminum, silicon, or manganese) may be added to enhance specific characteristics and colors. A higher level of zinc or silicon will make the brass stronger, for example, while the addition of iron will give it magnetic qualities.

Brass is highly formable with a low melting point, and it’s non-ferromagnetic, making it easy to separate to recycle. Desirable brass properties include high corrosion resistance, which can be improved even further by including a larger amount of manganese in the brass, and good thermal and electrical conductivity. However, it is likely to crack if placed under significant stress.

Brass is commonly used in a variety of applications:

- Decorative items and trim

- Musical instruments

- Pipes and tubing

- Electrical components

What Is the Difference Between Copper and Brass?

While copper is a naturally existing base metal, brass is an alloy: a man-made combination of copper and zinc. Brass can feature a variety of characteristics depending upon how much zinc and other metals are mixed with the copper, but brass and copper properties are similar. Copper is antimicrobial, which makes it useful in high-touch applications and medical facilities. Because brass contains copper, it retains those antimicrobial properties. Both materials will oxidize and develop a patina, which for some applications is a desired decorative look. If not, you can seal the brass or copper item to prevent exposure to air.

With its high conductivity, copper is a popular choice for wires and electrical components, while various types of brass find more uses in industrial and consumer goods. Take a look at these key differences between the materials to help you determine whether brass or copper is a better choice for your application:

- Copper is completely electrically conductive, while a brass alloy offers some electrical resistance, depending on the amount of each alloyed metal.

- Brass offers better corrosion resistance.

- Copper has a higher melting point: 1084° C compared to brass at 900° C to 940° C.

- Brass is harder than copper, and the more zinc the brass alloy contains, the harder it will be.

- Brass features higher machinability, weldability, yield strength, and shear strength.

- Copper is usually more expensive than brass, though it can depend on the specific alloy and the material quality.

Whether you go with brass or copper will depend on the environmental conditions and unique stresses your finished product will face. Each metal offers advantages for specific applications.

At Sequoia Brass & Copper, we source copper, bronze, and brass alloys in sheets, tubes, bars, plates, and rods, and we specialize in hard-to-find shapes and alloys. Since 1983, we’ve been committed to working with only high-quality metals while offering competitive pricing, clear communication, quick service, and expert guidance for our clients. With our years of experience in the industry with both domestic and international metal sources, we can connect you with the materials you need for projects of all sizes. Contact us to learn more, or request a quote for your project.