CDA 932 bearing bronze—also known as SAE 660, C93200, and leaded tin bronze—is a copper-alloy that contains large amounts of lead, tin, and zinc and traces amounts of iron, nickel, and antimony. As the standard material for light-duty applications, it demonstrates excellent strength, machinability, and resistance to wear and corrosion from seawater and brine. Additionally, when used in machining operations, it retains its shape and accommodates journal irregularities and lower lubrication levels. For general industrial use, bearing bronze has the necessary properties to comply with ASTM B505, ASTM B271, SAE J461, and SAE J462 standards.

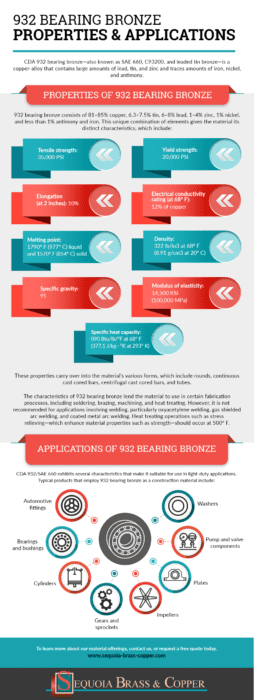

Properties of 932 Bearing Bronze

932 bearing bronze consists of 81–85% copper, 6.3–7.5% tin, 6–8% lead, 1–4% zinc, 1% nickel, and less than 1% antimony and iron. This unique combination of elements gives the material its distinct characteristics, which include:

- Tensile strength: 35,000 PSI

- Yield strength: 20,000 PSI

- Elongation (at 2 inches): 10%

- Electrical conductivity rating (at 68º F): 12% of copper

- Melting point: 1790º F (977º C) liquid and 1570º F (854º C) solid

- Density:322 lb/in3 at 68º F (8.91 g/cm3 at 20º C)

- Specific gravity:91

- Modulus of elasticity: 14,500 KSI (100,000 MPa)

- Specific heat capacity:090 Btu/lb/°F at 68° F (377.1 J/kg · °K at 293° K)

These properties carry over into the material’s various forms, which include rounds, continuous cast cored bars, centrifugal cast cored bars, and tubes.

The characteristics of 932 bearing bronze lend the material to use in certain fabrication processes, including soldering, brazing, machining, and heat treating. However, it is not recommended for applications involving welding, particularly oxyacetylene welding, gas shielded arc welding, and coated metal arc welding. Heat treating operations such as stress relieving—which enhance material properties such as strength—should occur at 500° F.

Applications of 932 Bearing Bronze

CDA 932/SAE 660 exhibits several characteristics that make it suitable for use in light-duty applications. Typical products that employ 932 bearing bronze as a construction material include:

- Automotive fittings

- Bearings and bushings

- Cylinders

- Gears and sprockets

- Impellers

- Plates

- Pump and valve components

- Washers

932 Bearing Bronze Offerings From Sequoia Brass & Copper

At Sequoia Brass & Copper, we offer 932 bearing bronze in cut-to-order solid bars, rods, and tubes. They are available in the following sizes:

Solid Bars: 3/8 to 12 inches (diameter)

Rods: 0.375 to 8 inches (outer diameter) and 6.5 to 13 inches (length)

Tubes: 0.5 to 9.5 inches (inner diameter), 1.25 to 10.5 inches (outer diameter), 0.375 to 1.5 inches (wall thickness), and 6.5 or 13 inches (length)

Contact Sequoia Brass & Copper Today

Sequoia Brass & Copper is an industry leader in the supply of non-ferrous metals, including 932 bearing bronze. By partnering with us for their brass, bronze, and copper needs, our customers benefit from our:

- Stringent quality management system

- Competitive pricing and shipping rates

- In-house, close tolerance cutting capabilities

For more information on our bronze product offerings, including 932, view our bronze products page or shop our bronze products catalog. For additional questions about our materials or to place an order, contact us or request a free quote today.