Since 1983, Sequoia Brass & Copper has been serving the metal fabrication industry with high-quality bronze, copper, brass, and other nonferrous metals in various shapes and forms. We adhere to extremely strict quality and purity standards so that our clients can rely on us to meet and exceed their requirements.

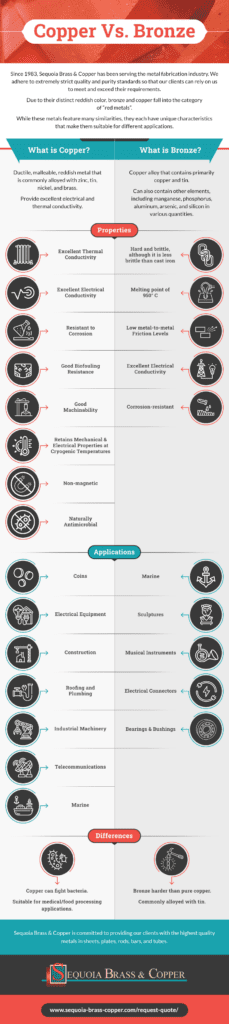

Due to their distinct reddish color, bronze and copper fall into the category of “red metals”. While bronze is a copper-based alloy, bronze exhibits more hardness than pure copper and typically contains other elements that produce various properties. While these metals feature many similarities, they each have unique characteristics that make them suitable for different applications.

What Is Copper?

Copper is a ductile, malleable, reddish metal that is commonly alloyed with zinc, tin, nickel, and brass to yield different properties. Copper and copper alloys provide excellent electrical and thermal conductivity, which makes them popular for use in electronics and a wide range of other uses. It can also be easily soldered, or brazed.

Copper Applications

Copper’s many desirable features make it suitable for a wide range of applications, including:

- Coins

- Electrical equipment

- Construction

- Roofing and plumbing

- Industrial machinery

- Telecommunications

- Marine

Copper Properties

Properties of copper include:

- Excellent thermal conductivity

- Excellent electrical conductivity

- Resistant to corrosion

- Good biofouling resistance

- Good machinability

- Retains mechanical and electrical properties at cryogenic temperatures

- Non-magnetic

- Naturally antimicrobial

What is Bronze?

Bronze is copper alloy that contains primarily copper and tin. Bronze can also contain other elements, including manganese, phosphorus, aluminum, arsenic, and silicon in various quantities to produce different properties.

Applications

Bronze alloys are preferred in a wide variety of applications, including:

- Marine. Due to its corrosion resistance, bronze is a popular choice for boats and other marine-exposed applications such as ship propellers and fittings.

- Sculptures. Its muted gold tone and aesthetic appearance make bronze a common material for sculptures and other pieces of art.

- Musical instruments. Bells, cymbals, and other musical instruments are often made of bronze.

- Electrical connectors. Certain varieties of bronze alloys provide great electrical conductivity, making them useful in a wide range of electrical applications such as connectors and springs.

- Bearings and bushings. Bronze alloys are good for bushings and bearings in high-stress environments because of their minimal metal-to-metal friction levels.

Bronze Properties

Bronze alloys are reddish-brown in color and possess properties that enable them to be used in many applications, such as those listed above. The properties of bronze include:

- Hard and brittle, although it is less brittle than cast iron

- Melting point of 950° C

- Low metal-to-metal friction levels

- Excellent electrical conductivity

- Corrosion-resistant

What are the Differences Between Copper and Bronze?

There are many differences between bronze and copper. Bronze is an alloy, or mixed metal, consisting primarily of copper as well as various other elements. Because bronze is commonly alloyed with metals like tin, it is much harder than pure copper. While bronze is easier to fuse and cast, copper has an impressive ability to fight bacteria, making it suitable for industries such as medical and food processing.

Partner With Sequoia Brass & Copper

Both bronze and copper have an impressive range of properties that make them suitable for use in various applications and industries. Sequoia Brass & Copper is committed to providing our clients with the highest quality metals in sheets, plates, rods, bars, and tubes. To learn more about bronze, copper, or other metals we provide, contact us or request a quote today.