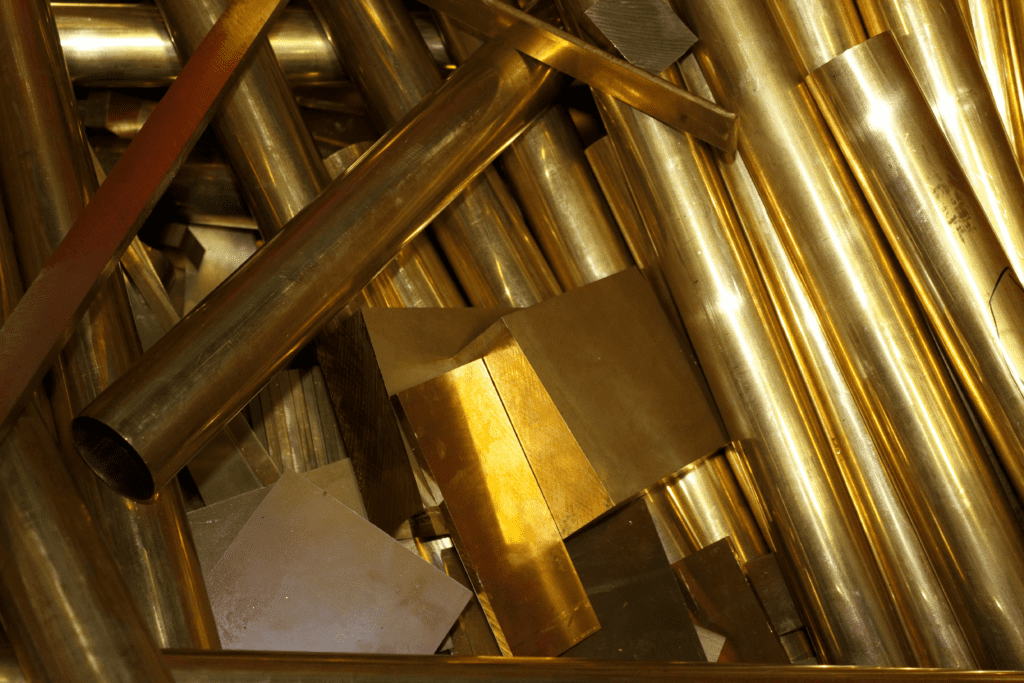

Sequoia Brass & Copper supplies an extensive inventory of Brass metals.

Brass is an alloy made of primarily Copper and Zinc. With a varied color appearance, Brass is most commonly used for musical instruments, architecture, automotive, electrical, and industrial projects. Brass metals are easy to cast and have a relatively low melting point. We carry Brass metals in bar, rod, sheet, plate, tube, and pipe shapes with stock sizes and online sizes listed in the tabs. All Brass products can be slit or cut to order to your specifications by submitting a request for quote form. With our competitive pricing and shipping rates, there is no need to look anywhere else to find high quality Brass metals.

We have been serving the metal fabrication industry since 1983. Sequoia Brass & Copper is a service-oriented company. We are dedicated to providing the highest quality in both materials and customer response. Contact us for size, weight, and pricing information or call 1-800-362-5255.